“It seems to be a law of nature, inflexible and inexorable, that those who will not risk cannot win.” John Paul Jones

How do you go about “taking charge of risk?” Does your company or organization deliberately address risk? Do you drive responsibility for risk control to the appropriate level with accountability? Is your entire team involved with the process? Do your leaders take charge? How healthy is your culture?

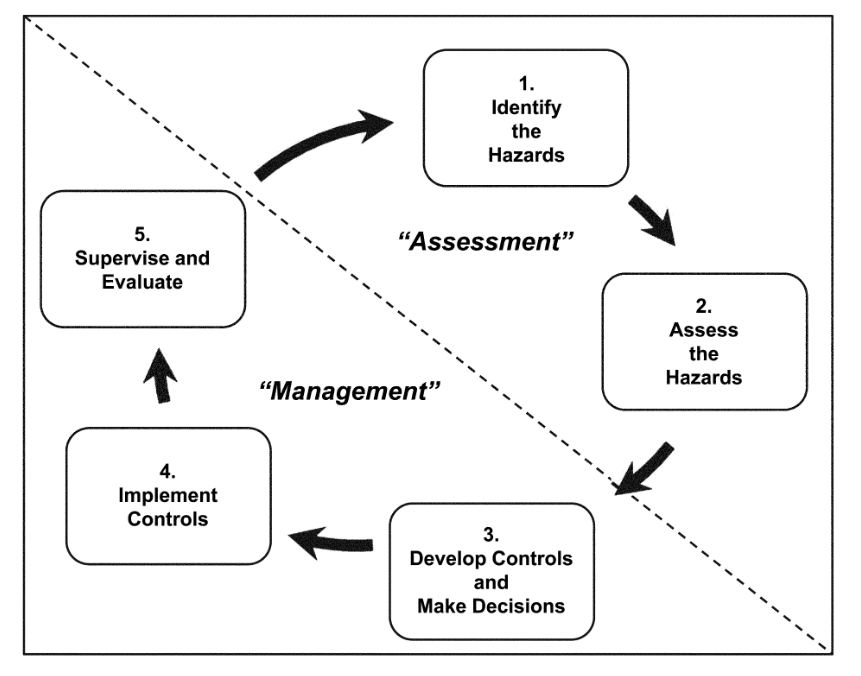

When bad things happen, the After Action Review will invariably identify a number of “planets” that were lined up to allow it all to happen, to include serious accidents, higher workers’ comp expenses, poor customer service, loss of market share, and lost revenue. Yet,it doesn’t have to be a slippery slope. In the US Army, we learned to rely upon a simple 5-Step Risk Assessment process that effectively identified and mitigated strategic, operational, and tactical risk. (Step 1 – Identify the Hazards, Step 2 – Assess the Hazards, Step 3 – Develop Controls and Make Risk Decisions, Step 4 – Implement Controls, Step 5 – Supervise and Evaluate)

The process was incorporated into any planning process, from developing a live-fire training exercise, to deploying a force to the Balkans or the Middle East, to planning an attack to defeat an enemy. In the corporate world, we employ the same process every time we conduct strategic planning, open up a new branch of the company, acquire a new business, roll out a new product, stand up a new manufacturing center, open up a new delivery route, or take on a new customer. The process covers lots of ground. How does it work?

Similar to the After Action Review, you begin by involving the entire team needed to address whatever plan you are addressing…include all those who impact the success or failure of the new task or mission. Think cross functional. Remove silos. For example, the strategic planning process should include a risk assessment that involves the company leader team. A risk assessment for a new delivery route should include all those involved in the process, to include sales, customer service, the safety manager, and operations with route planners, truck loaders, and drivers. The object is to involve a cross functional team to address the totality of the task. All you need is up to one hour of uninterrupted time, chart paper, and a marker to capture the process. The end state is transparency, empowerment, commitment, teamwork, and your best shot at identifying and mitigating risk.

Image source: US Army

Let’s quickly break down the five steps.

Step 1: The leader defines the new task or mission and facilitates a brainstorming session to identify all the hazards. Hazards will fill a number of buckets, and depending on the task, might include safety, market forces, the competition, operational factors, and financial impacts. Get it all down on chart paper. Energize the creative juices of every team member. There are no bad ideas. Every idea counts.

Step 2: Assess the hazards to determine risk. Assess the impact of each hazard in terms of potential loss and cost based on probability and severity. Then, prioritize the hazards into buckets of high, medium, and low risk.

Step 3: Start with the high risk bucket and develop controls for each hazard. Identify changes to the plan or control measures to eliminate the hazard or reduce the risk to a lower level. Controls may drive changes to SOPs and procedures. As control measures are developed, re-evaluated the hazards until the residual risk is at a level where the benefits outweigh the cost. High risk hazards that cannot be mitigated may cause a decision to find a different course of action.

Step 4: Implement controls that eliminate or reduce the hazards. Assign responsibility for each hazard bucket. For example, the CEO or COO may retain responsibility for approving plans for high risk hazards. Medium and low risk planning and implementation may be delegated to managers and supervisors, respectively. Ensure the controls are communicated and understood by the entire team. Whatever you decide, do it.

Step 5: Supervise and evaluate. Enforce standards and controls. Leaders need to be in charge and self-discipline needs to be part of the ethos of your team. Team members are expected to “do the right thing in the absence of supervision”. Along the way, evaluate the effectiveness of controls and adjust as necessary. Ensure lessons learned are fed back into the system for future planning.

This simple and elegant process is all about exposing and avoiding unnecessary risks. Starting with the highest risks, then identify and implement controls to “throw the planets out of alignment”. The impact will be dramatic and improve your chances for success. You’ll be amazed how accidents will be reduced and your workers’ comp expenses will be all but eliminated. Give it a try!